When you use an oscillating tool, the blade you pick makes a big difference. The right blade helps you work faster. It cuts cleaner. It even keeps your tool from wearing out too soon.

But here’s the big question you may be asking: Are oscillating tool blades universal?

The short answer is no. But don’t worry. Many blades still work across different tool brands. This guide will help you understand how blade compatibility works. You’ll also learn which blade is best for each job—wood, metal, grout, and more.

Let’s start by understanding blade compatibility.

Are Oscillating Tool Blades Universal?

You might hope that all blades work with all tools. Sadly, that’s not the case. Many brands make their own blade mounts. These mounts don’t always match with others.

Some tools use what’s called a Starlock system. Others use something known as OIS. A few come with a quick-release setup. These differences can cause problems when switching blades. Luckily, many blades now come in a “universal fit.” These are designed to work with most brands. You might still need an adapter for some tools. But for the most part, you can find a blade that fits your tool.

Types of Oscillating Tool Blades & Their Uses

When you’re using an oscillating tool, picking the right blade matters a lot. Each blade is designed for a specific task or material. Using the wrong blade can slow you down or even damage your project. Let’s explore the main types of blades and multi-tool blades you’ll find and what each one does best.

Cutting Blades

Cutting blades are the most common. You’ll use them the most for cutting wood, metal, or both. They come in different tooth styles and materials, depending on what you want to cut.

Wood-Cutting Blades

If you’re working with wood, these blades are your best friend. They have sharp, fine teeth designed to make clean cuts through wood fibers without splintering. They work great for trim, baseboards, door frames, and other woodworking tasks.

Wood blades come with different tooth counts. Finer teeth mean smoother cuts but slower progress. Coarser teeth cut faster but can leave rough edges. So, pick a blade that matches your project. If you’re cutting hardwood or plywood, a blade with carbide tips will stay sharp longer and cut cleaner.

One of the top blades for wood cutting is the Bosch Carbide-Tipped Wood Blade. It stays sharp and handles hardwood easily. This blade fits many tools and delivers fast, smooth cuts. If you want to trim molding or cut framing lumber, this blade works well.

Metal-Cutting Blades

Metal is tougher than wood. To cut through nails, screws, pipes, or sheet metal, you need a blade made of strong steel or bi-metal. These blades have fewer, sharper teeth designed to withstand heat and wear.

Bi-Metal Durability: Our Titanium-coated blades slice through nail-embedded wood without losing their teeth.

Metal-cutting blades usually last longer because they are made from bi-metal or carbide. These materials resist dulling and breakage. The Bi-Metal Blade is a popular choice here. It cuts through thick nails, screws, and even thin metal sheets without slowing down.

If you’re working on a renovation or repair job that involves plumbing or electrical conduit, you’ll want a metal blade. Using a wood blade on metal can damage the blade quickly and ruin your cut.

Multi-Material Blades

Sometimes, you face a job with mixed materials—wood with nails, drywall with screws, or metal studs with wood framing. Changing blades every few minutes wastes time. That’s where multi-material blades shine.

A multi-material blade can cut through wood, metal, drywall, and more without needing a swap. These blades often have titanium coatings or bi-metal construction to handle different materials. The Titanium-Coated Blade is a favorite for multi-material work. It cuts wood, nails, and light metal fast and clean.

If you’re doing demolition or remodeling, a multi-material blade is your best bet. It keeps you moving and saves you money on multiple blades.

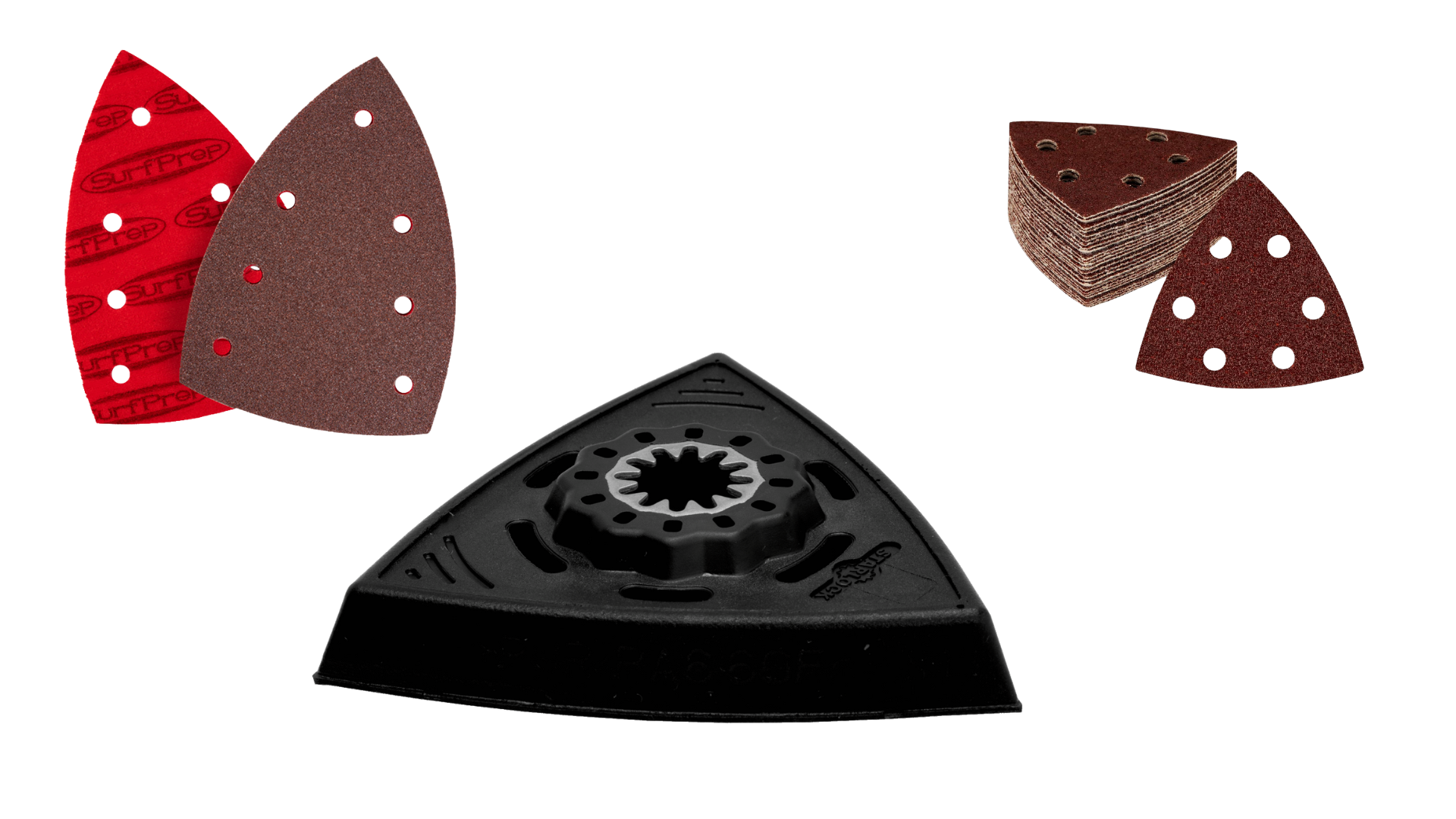

Sanding Attachments

Your oscillating tool can also sand small areas, edges, and corners where a big sander won’t reach. Sanding attachments come in handy for prep work and finishing.

Triangular Sanding Pads

These pads are shaped like a triangle, so they fit nicely into tight corners and along edges. The sharp points let you get into places like window sills, cabinet corners, or around molding.

The pads hold sanding sheets with a hook-and-loop system, similar to Velcro. This lets you swap out sandpaper quickly. You can use coarse grit for heavy sanding or fine grit for finishing.

If you want smooth surfaces without changing tools, a sanding attachment is perfect. It’s especially handy when you’re working on furniture or small woodworking projects.

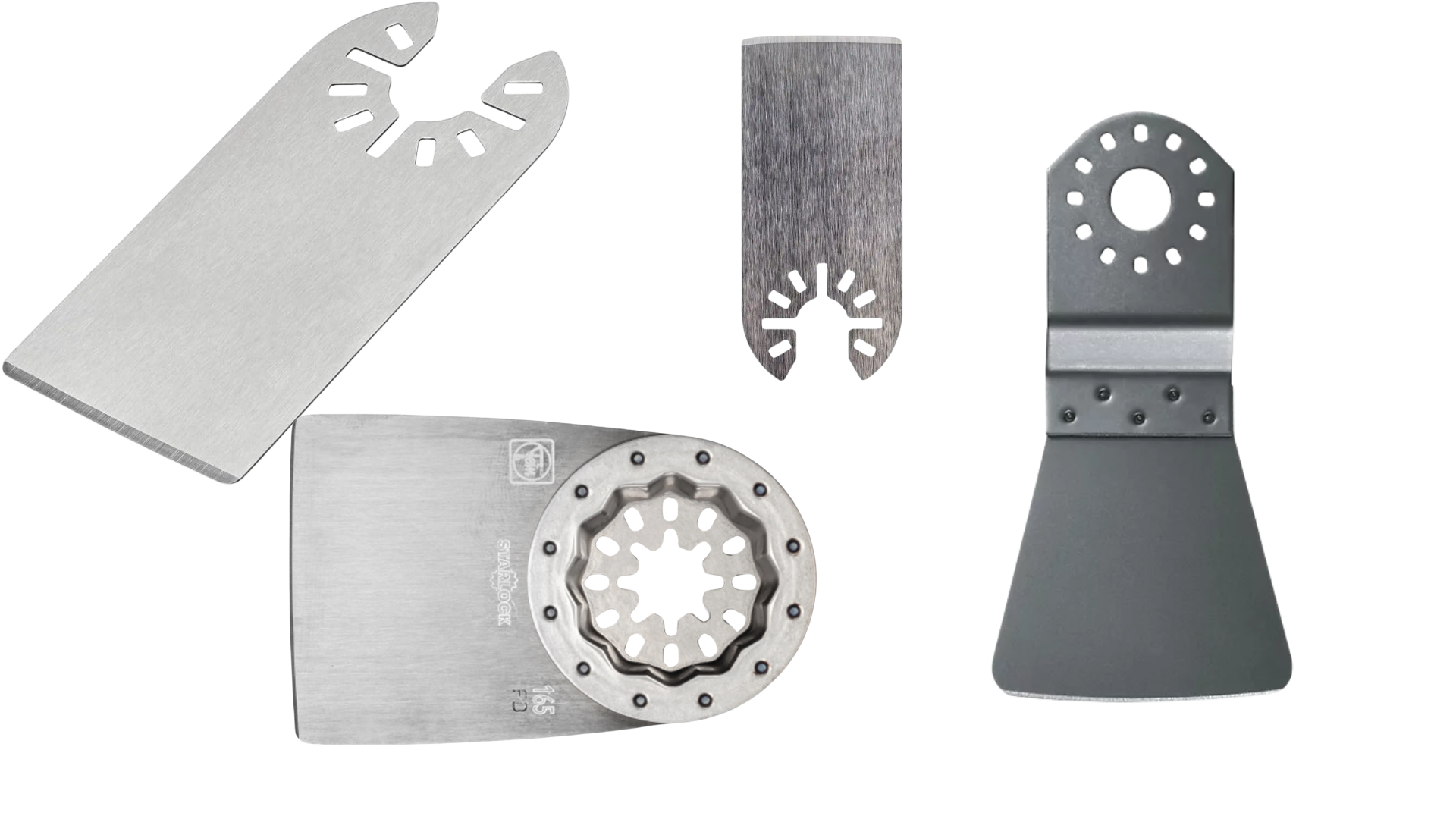

Scraper Blades

Sometimes you need to remove old paint, glue, or caulk. Scraper blades help you do this quickly and cleanly.

Rigid Scraper Blades

Rigid scrapers are stiff and strong. They work well on dried paint, hardened adhesives, and even thin layers of flooring glue. You push or pull the blade under the material, and it lifts it away.

These blades don’t bend much, so they provide good force for scraping. They’re great for prep work before painting or refinishing.

Flexible Scraper Blades

Flexible scrapers bend more easily. This makes them ideal for softer materials like carpet glue or vinyl flooring adhesive. The flexibility lets the blade follow uneven surfaces without damaging the base.

If you’re doing flooring removal or delicate scraping, a flexible blade is safer. It reduces the chance of gouging the surface beneath.

Grout Removal Blades

Tile work requires special blades. Removing grout or cutting tile is tough on blades, so they need to be durable and abrasive.

Carbide grit blades are coated with tiny, hard particles. These help grind away grout without chipping the surrounding tile. Use them to clean out old grout before re-grouting or replacing tiles. They don’t cut like saw blades. Instead, they abrade the grout for easy removal.

How to Choose the Right Oscillating Tool Blade for Your Project

Your project decides your blade. It’s that simple. Here’s what you need to know. Working with wood? Choose oscillating multi tool blades with fine teeth for efficient cutting, not a curved edge. A carbide-tipped one is even better for hardwood or treated lumber.

Cutting metal? Pick a bi-metal blade. If you need to cut thick nails or bolts, go with a carbide-tipped option. Removing grout or tiles? Use a blade with a diamond or carbide grit edge. These materials can handle tougher material surfaces like stone.

Doing demolition? Then, a multi-material blade is your best friend. It slices through mixed materials without blinking. Don’t forget—if a blade wears out fast, it may not be the right one. Always match the blade to the job.

Best Oscillating Tool Blades for Different Materials

Let’s look at the different types of top blade choices. Each blade type is designed for different materials. These picks give great performance, last longer, and fit most tools.

Best Blades for Cutting Wood

The Johnson Tools Starlock Carbide Blade is perfect for wood. It cuts fast and clean, making it good for most DIY enthusiasts. If your tool supports Starlock, this blade is hard to beat. Don’t have Starlock Max? The DeWalt Titanium-Coated Wood Blade is a solid choice. It works with most universal-fit tools, including plastic. Plus, it’s durable and budget-friendly.

Best Blades for Cutting Metal

One Blade, Many Tools: Johnson Tools’ universal fit system connects seamlessly with 95% of major oscillating tool brands.

The Diablo Carbide-Tipped Blade stands out for metal work. It cuts thick screws and nails with no problem. You’ll get long life and less vibration. For tougher metals like stainless steel, try the Fein Starlock Plus Blade. It’s made for hard jobs and runs cool under pressure.

Best Multi-Material Blades

Need one blade for everything? The Milwaukee Titanium Coated Bi-Metal Blade is a winner. It can tackle wood, nails, and even some metals.

The Johnson Tools Oscillating Multi-Material Blade is also great for mixed work with different applications. It shines in demolition jobs where you’re cutting through several materials at once with great power transfer.

FAQs About Oscillating Tool Blades

You may still have some questions. Let’s clear up the most common ones.

Can I use any oscillating blade on my tool?

No. Always check your tool’s mount. Some need Starlock or OIS blades. Others accept universal types.

What’s the best blade for hardwood?

Go with a carbide-tipped wood blade. It lasts longer and handles dense wood better.

How do I make blades last longer?

Don’t rush. Let the tool do the work. Use a slow speed on hard materials. Clean blades after use and store them dry.

Conclusion

Now you know that not all blades are the same. Some are brand-specific. Some need adapters. Many are universal—but not all. The most important thing? Pick the right blade for the job. Use a wood blade for trim, a bi-metal blade for metal, and a carbide blade for grout or tile. If you’re doing a bit of everything, a multi-material blade is the way to go.

Quality matters, too. A good blade lasts longer and gives better results. That means fewer blade changes and a smoother project. Need a reliable supplier for oscillating blades? [Contact Johnson Tools] today for free samples and a compatibility consultation.

FAQ: Oscillating Blade Compatibility & Purchasing Guide

Q1: Do your universal blades fit Starlock machines?

A: Most standard universal blades fit OIS and standard quick-release tools (like Makita, Milwaukee, DeWalt). For Starlock machines (specifically Fein and Bosch newer models), you need blades specifically designed with the Starlock 3D interface. We offer both universal and Starlock-compatible blade options—[contact us] to specify your machine type.

Q2: Can I brand these blades with my own logo (OEM)?

A: Yes, Johnson Tools specializes in OEM manufacturing. We can laser-etch your brand logo onto the blades and provide custom packaging (blister packs or bulk boxes) suitable for retail or industrial distribution.

Q3: What is the difference between Bi-Metal and High Carbon Steel (HCS) blades?

A: HCS blades are cost-effective and best for softer materials like wood and plastic. Bi-Metal blades feature high-speed steel teeth, making them durable enough to cut through wood with nails and light metals. For the toughest jobs (hardened screws, bolts), we recommend our Carbide-tipped series.

Q4: Do you offer bulk discounts for construction supply stores?

A: Absolutely. We provide tiered wholesale pricing for distributors and construction supply retailers. Whether you need a 10-piece sample pack or a 5,000-piece container order, we can accommodate your volume needs. [Request a wholesale price list here].